Vertical Carousel Modules vs. Horizontal Carousel Modules: Which Is Better for Your Warehouse?

Choosing the right storage solution for your warehouse is crucial to your business operations. Two popular options are vertical carousel modules and horizontal carousel modules. These modules are designed to save space and increase efficiency within your warehouse.

Vertical Carousel Modules

Vertical carousel modules are a type of automated storage solution that uses a chain-driven system to rotate shelves vertically. This system allows for the maximum amount of storage within a small footprint. Vertical carousels are typically used to store smaller items such as documents, tools, and parts. They are ideal for facilities with limited floor space as they can store a large number of items without taking up too much space.

Benefits of Vertical Carousel Modules:

- Space-Saving: Vertical carousels take up very little floor space, which makes them ideal for warehouses with limited space.

- Increased Efficiency: Vertical carousels are designed to deliver items to the operator, which eliminates the need for manual searching and reduces the time it takes to retrieve items.

- Improved Inventory Management: Vertical carousels are automated and can be integrated with inventory management software, enabling real-time tracking of inventory levels.

- Easy to Install: Vertical carousels can be installed on any stable floor surface without the need for additional structural support.

Horizontal Carousel Modules:

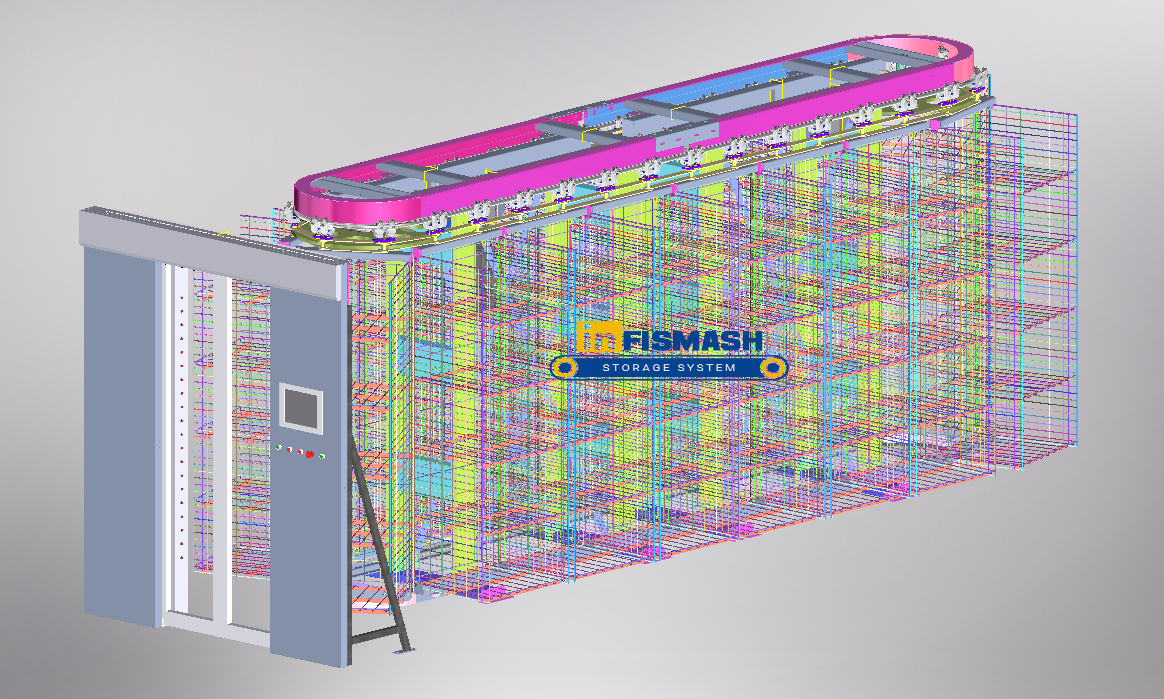

Horizontal carousel modules, also known as horizontal carousels, are automated storage systems that rotate horizontally on a track. These carousels are typically used to store bigger items, such as boxes, equipment, and furniture. Horizontal carousels are more suitable for facilities with a substantial amount of floor space, as they require more space than vertical carousels.

Benefits of Horizontal Carousel Modules:

- Increased Storage Capacity: Unlike vertical carousels, horizontal carousels can store bigger and heavier items, which means they can store a higher volume of goods.

- Improved Productivity: Horizontal carousels allow for faster access to items, which reduces the time it takes to retrieve items, and increases productivity.

- Customizable: Horizontal carousels can be customized to meet specific storage requirements, such as size and weight capacity.

- Space Optimization: Horizontal carousels can be integrated with high-density storage solutions, such as pallet racking, to optimize warehouse space and increase storage capacity.

Which Is Better for Your Warehouse?

The decision to choose between vertical carousel modules vs. horizontal carousel modules depends on several factors, such as your warehouse’s available floor space, the size, and weight of the items you need to store, and the level of automation required.

If you have limited floor space and need to store smaller items, vertical carousel modules may be the best choice. On the other hand, if you have larger items to store and have more floor space available, horizontal carousel modules may be the better option.

Ultimately, the choice comes down to your specific requirements and the resources available to you. By taking the time to evaluate your warehouse’s storage needs, you can make an informed decision on which storage solution will work best for your business.