Double side sticker labeling machine

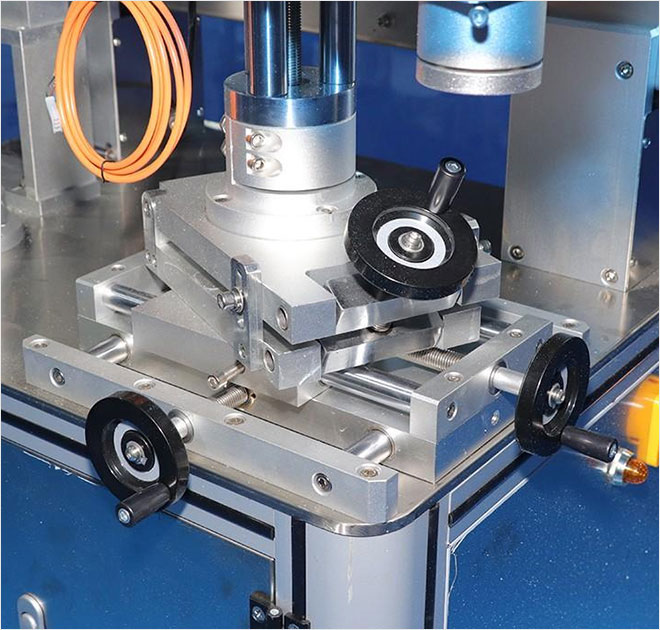

Automatic double side sticker labeling machine is one of the most user-friendly labeling machines. The double sided labeling machine is used for full/partial labeling of flat or rectangular containers of different sizes. Depending on the product and label size, it can label up to 120 containers per minute. The fully automatic double-sided adhesive labeling machine model is equipped with a roller spacer device, which is simple to operate and “no need to replace parts”.

Double side sticker labeling machine operation

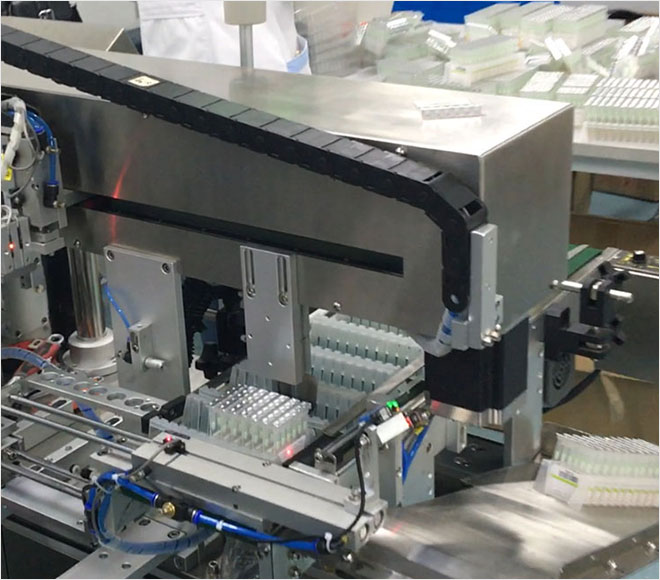

The filling and sealing or empty bottles received from the turntable are conveyed from the conveyor, a bottle separator attachment is provided on the same conveyor to separate the bottles from continuous movement, and two pressing devices are provided on the conveyor to pull the bottles Straight and after the straight top pressure device picks up the bottle through the top pressure device and picks up the bottle to its original position. The side pressure device releases the bottle in the release part to provide a sensor to detect the product. After the sensor is sensed, the command is issued and the operation is steeper or Servo motor releases the label gap when a label is applied. The sensor issues a command. During the release of the label, the servo or stepper provides a brush to press the label and remove the air between the labels. After the bottle cycle is completed, a labeling operation is completed, and the conveyor belt removes the bottle. Take to the next operation.

Applicable industries of double side sticker labeling machine

Through the optional labeling device and cylinder positioning mechanism, it can simultaneously complete the functions of rolling and positioning the bottle body of the round bottle at the same time. It is suitable for flat, Multifunctional automatic labeling on single and double sides of square, round and taper products.

Kenwei’s double sided adhesive labeling machine is suitable for high-speed production lines and a variety of applications in a wide range of industries. These machines can apply pressure-sensitive labels on both sides of the product at a time, thereby increasing efficiency and providing multiple labeling options for full flexibility. Your product passes through the top and/or bottom linear labeling machine, where two pressure-sensitive labeling machines press the labels on both sides of the container. This provides more opportunities to add important information to your product labels and brand details.

Kenwei’s double sided linear labeling machine series are known for consistently achieving industry-leading efficiency and reliability at the highest linear line speeds. Learn more about our double side sticker labeling machine and how they are suitable for your product line.

Product features of double side sticker labeling machine

- Powerful function, one machine can realize single-sided and double-sided labeling of 4 kinds of products (round bottle, flat bottle, square bottle, special-shaped bottle).

- The double sided rigid plastic synchronous guide chain is adopted to automatically ensure the neutrality of the bottle. It has low requirements for the worker to put the bottle and the assembly line to connect the bottle, which greatly reduces the difficulty of the worker’s work or the assembly line. It can be produced on a single machine or connected to an assembly line.

- Equipped with an elastic pressing mechanism to ensure stable product delivery and effectively eliminate the inherent error of bottle height.

- Equipped with an automatic bottle separation mechanism, the spacing is automatically separated before the bottle guide, to ensure the stability of the subsequent bottle guide, conveying and labeling.

- Equipped with a double labeling mechanism to ensure labeling accuracy for the first time, and one-time squeeze labeling, which can effectively eliminate e-bubbles and ensure that the labels are tightly attached to the head and tail.

- Intelligent control, automatic photoelectric tracking, with the functions of nothing but no labeling, automatic correction without label and automatic label detection, to avoid wasting labels and missing labels.

- The main material of the equipment is stainless steel and high-grade aluminum alloy, which conforms to GMP production specifications, and has a firm overall structure and beautiful appearance.