Intelligent Dual-module Silo Systems

Introduction

Begin with an overview of modern storage challenges in electronics manufacturing, particularly for SMD (Surface Mount Device) components and SMT (Surface Mount Technology) production lines. Highlight the need for intelligent, automated solutions that ensure component protection, traceability, and efficiency.

The Intelligent Dual-module Silo, designed for automated reel storage and retrieval, brings a revolutionary shift to SMD (Surface-Mount Device) material management. With its modular design, dual-lane mechanism, and intelligent inventory system, it is an ideal solution for enhancing productivity, accuracy, and traceability in electronics manufacturing environments.

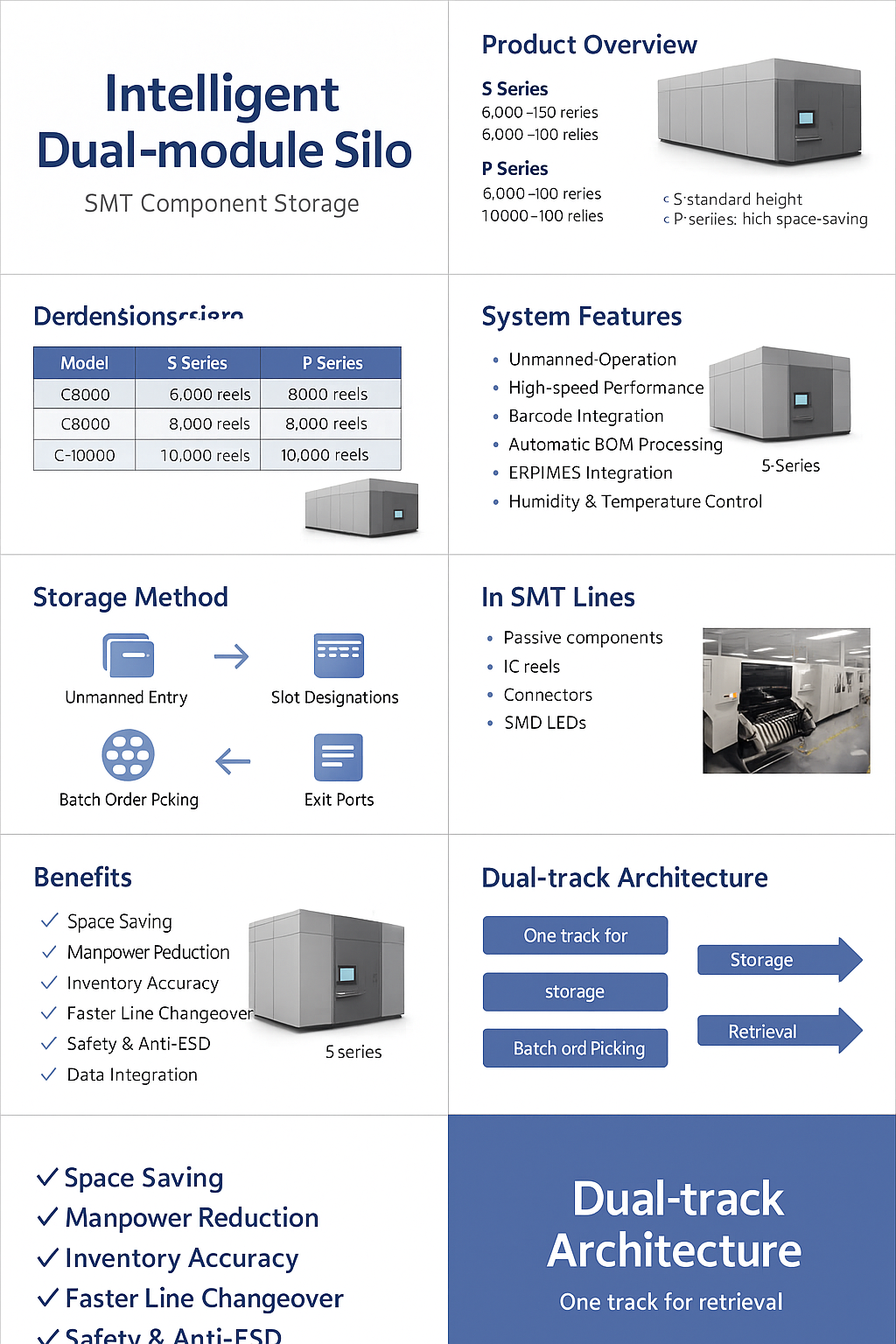

1. Product Overview

The Intelligent Dual-module Silo—available in both S series (Standard Height) and P series (High Cabinet, Space-Saving) models—provides fully automated storage for SMT component reels. It supports integration with MES/ERP systems, features barcode scanning, environmental monitoring, and allows high-speed access to thousands of reels.

Model Types & Reel Capacities:

- C-6000 Series: 6,000 reels

- C-8000 Series: 8,000 reels

- C-10000 Series: 10,000 reels

2. Design & Space Optimization

Two structural variants are provided:

- S Series (Recommended for Exit Port Areas)

Designed with standard box height, offering easier integration with pick-and-place lines and external conveyors. - P Series (Space-Efficient High Cabinet)

Offers the same reel capacity while occupying a smaller footprint by utilizing vertical space.

| Model | S Series (L×W×H) | P Series (L×W×H) |

|---|---|---|

| C6000 | 7400×2400×2400 mm | 6200×2400×2800 mm |

| C8000 | 9900×2400×2400 mm | 7400×2400×2800 mm |

| C10000 | 9900×2400×2800 mm | 7400×2400×2800 mm |

3. Automation & Efficiency

The Intelligent Dual-module Silo dramatically improves storage and retrieval operations:

- Unmanned Operation: Fully automated material entry/exit.

- Batch Picking: System groups orders to reduce waiting time.

- High-Speed Performance:

- C6000: 5 seconds per reel

- C8000: 6 seconds per reel

- C10000: 8 seconds per reel

- Maximum Throughput: Up to 16,000 reels/day.

4. Storage Method

Reels are stored using a robotic system that handles max 50 reels per batch. Components are scanned upon entry and placed in designated slots based on system optimization algorithms. During retrieval, reels are picked according to batch orders and delivered sequentially to exit ports.

5. Functional Highlights

- Barcode Integration: Supports 1D/2D barcode scanning, 300×400mm reading range.

- Automatic BOM Processing: Links reel barcode with BOM, allowing direct component matching and error reduction.

- Static-Safe Handling: Supports both paper and plastic tape reels with anti-static protection.

- ERP/MES Integration: Open interface for real-time data sync with production management systems.

- Humidity & Temperature Control: Operating range: 10°C–35°C; humidity 25%–75% RH with sensor feedback.

- Modular Expandability: Compatible with AGVs, robotic arms, mechanical feeders, visual positioning, and more.

- Environmental Requirements:

- Power: AC200V–230V, 50/60Hz, max 3.0KVA

- Air Pressure: 0.5Mpa, air consumption 100L/min

6. Use Cases in SMT Lines

The Intelligent Dual-module Silo is widely used in SMT factories for storing:

- Passive components (resistors, capacitors)

- IC reels

- Connectors

- SMD LEDs

- Coils, crystals, and other electronic components in 7″/8mm, 7″/12mm formats

Its integration into SMT lines eliminates human error, reduces downtime, and guarantees real-time material traceability.

7. Benefits & ROI

✅ Space Saving

- Compared to traditional racking, P series saves up to 30% floor space.

✅ Manpower Reduction

- Eliminates manual inventory tasks, reducing operator workload.

✅ Inventory Accuracy

- Prevents mismatch or loss of materials via barcode traceability.

✅ Faster Line Changeover

- Supports rapid reel retrieval for efficient production line changeovers.

✅ Safety & Anti-ESD

- Static-free internal environment protects sensitive components.

✅ Data Integration

- Seamless interface with existing systems ensures synchronization across departments.

8. Why Dual Module?

The dual-track (双导轨) architecture supports simultaneous operations:

- One track for storage

- One for retrieval

This parallelism significantly boosts efficiency and minimizes material waiting time.

9. Installation & Customization

The system can be customized according to factory needs:

- Optional white anti-static exterior or custom colors

- Configurable expansion units

- Adjustable reel size compatibility

- External conveyor interface and automation modules

10. Future Outlook

As more SMT factories transition to smart manufacturing, storage automation will become standard. The Intelligent Dual-module Silo will play a pivotal role by:

- Supporting “lights-out” factories

- Reducing cost per unit

- Improving production flexibility

- Enabling real-time inventory analytics

With continual upgrades, the next-generation models will integrate AI for predictive storage and auto-replenishment capabilities.

Conclusion

The Intelligent Dual-module Silo is a powerful solution for modern SMT production environments seeking automation, efficiency, and smart inventory management. Whether you’re operating a high-mix low-volume (HMLV) production line or mass manufacturing PCBAs, this system is a cornerstone of digital transformation in electronic manufacturing.

Specifications

Intelligent Dual-module Silo – Model Specifications

S Series: Standard Cabinet Height (Recommended for Output Port)

P Series: Tall Cabinet, Smaller Footprint

| Model | P Series Footprint | S Series Footprint |

| C6000 | 15.5 m² | 16.75 m² |

| C8000 | 18.5 m² | 24.75 m² |

| C10000 | 24.75 m² | 24.75 m² |

Specifications Table

| Item | C-6000 Series | C-8000 Series | C-10000 Series |

| Reel Capacity | 6000 reels | 8000 reels | 10000 reels |

| Reel Size | 7″/8mm, 7″/12mm | ||

| External Dimensions | |||

| • S Series (L×W×H) | 7400×2400×2400 mm | 9900×2400×2400 mm | 9900×2400×2800 mm |

| • P Series (L×W×H) | 6200×2400×2800 mm | 7400×2400×2800 mm | 7400×2400×2800 mm |

| Storage Method | Unattended auto in/out, batch loading/unloading, max 50 reels | ||

| Retrieval Speed | Avg. 5 seconds/reel | Avg. 6 seconds/reel | Avg. 8 seconds/reel |

| Main Features | – Automated inbound/outbound via barcode and BOM – Supports paper/plastic reels (anti-static) – Open standard interface, MES/ERP integration | ||

| Barcode Reader | 1D/2D; Scan window 300×400mm; standard code types supported | ||

| Temperature / Humidity | Temp: 10–35°C; RH: 25%–75% (optional sensor monitoring) | ||

| Expandable Equipment | Compatible with sorting lines, AGVs, robotic arms, etc. | ||

| Power / Air Supply | AC200V–230V, 50/60Hz, max 3.0 KVA; Air: 0.5 MPa, 100 L/min | ||

| Finish & Appearance | White anti-static paint (customizable) | ||