The True Cost of a Missing Reel: How Smart SMT Storage Eliminates Production Chaos

In electronics manufacturing, the entire value of your production line hinges on having the right component at the right time. A multi-million-dollar SMT line can be brought to a standstill by a single, misplaced reel worth less than a dollar. This isn’t just an inconvenience; it’s a direct hit to your profitability.

If your team is still wrestling with static shelves, manual logs, and the daily “reel hunt,” you are fighting a losing battle against inefficiency. It’s time to stop managing chaos and start controlling your process with intelligent automation.

The Hidden Costs Draining Your SMT Line’s Profitability

Manual reel management creates a cascade of expensive problems that go far beyond wasted time.

| The Old Way (Manual Chaos) | The Infismash Way (Automated Control) |

|---|---|

| Costly Line Stoppages: Operators waste precious minutes—sometimes hours—searching for the correct reel, while your most expensive machinery sits idle. | Seconds-Fast Retrieval: The system delivers the exact reel to the operator in under 15 seconds, virtually eliminating downtime related to material searching. |

| Catastrophic Kitting Errors: A single wrong reel sent to the line can result in entire batches of PCBs being scrapped, leading to massive material waste and potential project delays. | Guaranteed 100% Kitting Accuracy: Software-driven picking, guided by LED pointers, ensures the right part is selected every single time, protecting your production quality. |

| “Black Hole” Inventory: Spreadsheets and manual counts are always out of date. You have no real-time visibility, leading to surprise stockouts or costly overstocking of components. | Perfect, Real-Time Inventory Visibility: Every transaction is automatically logged. You know exactly what you have, where it is, and when you need to reorder, all in real-time. |

The Solution: The Infismash Smart Component Tower

The **Infismash Smart SMT Reel Storage Tower** is more than just a cabinet; it is an intelligent, automated hub for your entire component workflow. It is purpose-built to integrate seamlessly into a modern electronics manufacturing environment and solve your most critical challenges at their source.

Stop fighting fires. The Infismash Tower prevents them from starting in the first place.

Transform Your Workflow with Intelligent Features:

- Automated “Goods-to-Person” Delivery: Operators scan a job, and the correct tray of reels is delivered to them at an ergonomic height. This eliminates wasted motion and speeds up kitting dramatically.

- Full MES/ERP Integration: Our system communicates directly with your existing manufacturing software, receiving pick lists electronically and updating inventory levels automatically for a truly connected workflow.

- Climate-Controlled, High-Density Storage: Protect your valuable and moisture-sensitive devices (MSDs) in a secure, compact, and controlled environment, storing thousands of reels in a minimal footprint.

- Complete Traceability: Every reel can be tracked by its unique ID, providing a full audit trail of who accessed what and when. This is critical for quality control and compliance.

Ready to End Production Delays Caused by Material Handling?

See for yourself how the Infismash Smart Tower can transform your SMT workflow. Schedule a quick, no-obligation online demo with one of our specialists.

Schedule Your Free Online DemoScalable Solutions for Any Size Operation

Whether you are a small contract manufacturer or a large-scale OEM, Infismash has a solution. Our **SMD Automated Storage Series** is fully scalable:

- Smart Material Tower: The perfect starting point for bringing intelligent, automated storage to your facility.

- Intelligent Silo Systems (Single & Dual Module): For larger operations requiring massive capacity and throughput, capable of handling over 16,000 reels per day.

- Complete Intelligent Warehousing Systems: A fully integrated solution that automates everything from receiving and labeling to storage and picking.

Invest in Uptime, Not Downtime

Don’t let outdated material handling processes undermine your investment in state-of-the-art SMT equipment. By automating your component storage with Infismash, you are making a strategic investment in smoother production, higher quality, and a stronger competitive advantage.

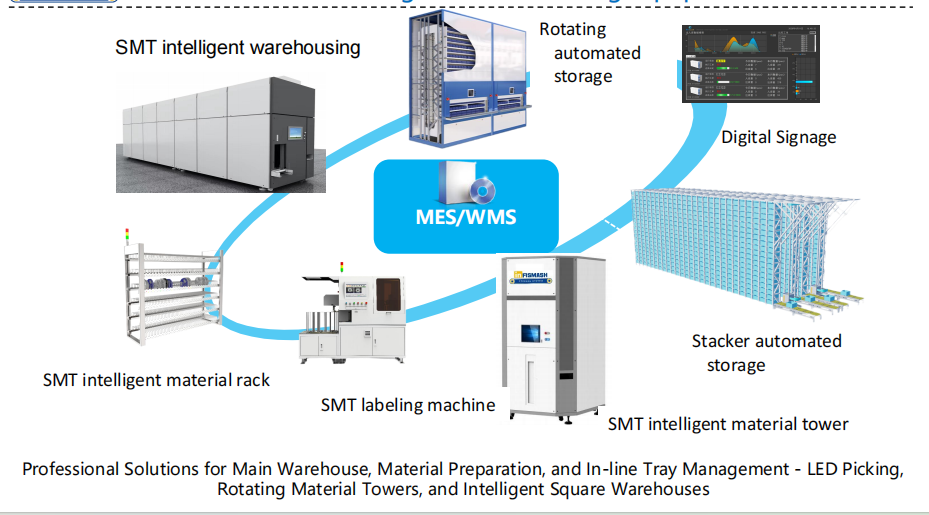

SMD Automated Storage Series

Infismash brings state-of-the-art automated SMD storage technology under one roof. From a simple storage tower to a complete warehouse system, we offer everything according to customers’ needs.

Through innovative design and advanced software, we make SMD storage extremely efficient and easier. They optimize storage by minimizing the footprint and offer excellent throughput for speedy access.

1)Smart Material Tower

The most basic yet advanced and intelligent SMD storage and retrieval solution. It has built-in trays with a reel capacity of up to 1,000 for optimized storage. It offers 1D/2D barcode recognition, temperature/humidity control, and MES/ERP integration.

2) Intelligent Single-module Silo

It takes SMD storage to the next level. Offers up to 4,000-reel capacity and daily throughput of over 8,000 reels. It is also AGV-compatible.

3) Intelligent Dual-module Silo

An ideal option for massive SMD storage and quick retrieval. The dual-module design boosts throughput up to 16,000 reels, which increases efficiency and production. It can offer storage for 6,000 to 10,000 reels.

4)Intelligent Warehousing System

A complete solution for SMD storage. From sorting to labeling and picking to storage, everything is controlled through the intelligent system. It makes SMD storage and retrieval better than ever before.

Ready to bring intelligent automation to your SMT material management?

Contact our electronics manufacturing experts to schedule a live online demo and see for yourself how Infismash can end your reel-finding nightmare.