Powder Coating Guns

Powder Coating Guns

powder coating uses the basic principle of electrostatic induction corona discharge electrostatic field. The process is like this: the electrostatic powder is fed into the spray gun by the air supply compressed air by the powder supply system, the metal diversion cup at the top of the spray gun is connected to the high voltage negative electrode, and the grounded device of the coated steel piece produces a positive level. A very strong electric field is generated between the spray gun and the workpiece. When the transport gas (air compression) sends the electrostatic powder from the powder supply tank to the diversion cup of the spray gun through the powder feeding tube, the arc discharge is generated because the diversion cup is connected to the negative pressure level, and a dense positive charge is generated around the powder. With negative electricity, under the effect of electrostatic force and air compression, the powder is evenly sucked on the workpiece, and the powder is melted and solidified (or plasticized) into a uniform, continuous, smooth and smooth polyurethane coating.

how powder coating works?

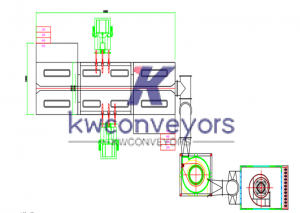

Top view of the big cyclone powder spray booth

powder coating: This is a liquid-like water-soluble resin coating replaced by a solid electrostatic powder. The electrostatic powder is negatively charged by a high working voltage, and is sucked on the surface of the coated workpiece of the grounding device by electrostatic attraction, and is heated and melted ( Or dry) to obtain a polyurethane coating. The electrostatic spray is a new technology and new technology. The commonly used electrostatic powder does not have liquid components such as organic solvents and dispersion media. It does not need to dilute the liquid and adjust the viscosity. It can not flow by itself, can flow after melting, and can not be like liquid paint. Stick to the surface of the workpiece. Therefore, the electrostatic spray has high spraying efficiency, high performance of polyurethane coating, solvent-free evaporation, low air pollution, low energy consumption, simple processing technology, short manufacturing cycle time, low cost of spraying, and easy maintenance of automatic spraying.

Spraying plastic powder will be charged according to the battery of the static electricity induction machine. Under the effect of the electrostatic field, the architectural paint will be sprayed onto the surface of the steel. The powder will be absorbed evenly on the surface of the workpiece to produce a powder coating. The powder coating is solidified after high-temperature baking, and the plastic particles will melt into a layer of high-density final protective coating with different actual effects; tightly adhered to the surface of the steel, and the sprayed products are mostly used indoors. The cabinet has a flat or matte finish. The spray powder mainly includes acrylate powder, polyester powder and the like.

The workpiece is prepared for spraying in advance according to the conveyor chain to the spray gun part of the spray booth. The electrostatic generator releases the static induction (negative level) according to the electric level needle of the spray gun grabbing the electric level needle to the workpiece orientation, and the static pressure induction makes the slave. The powdered and air-compressed compounds ejected from the lance are ionized (negatively charged) by their peripheral gas. The workpiece passes through the hanger according to the conveying connection ground (grounding device), so that an electrostatic field is generated between the spray gun and the steel piece, and the powder form reaches the surface of the steel piece under the two-way promotion of the electric field force and the air compression working pressure and is attracted by the electrostatic induction. Living on the surface of the steel produces a layer of symmetrical coating.

The powdered electrostatic spray is said to be anodized with the object to be coated, and the grounding device is normally used; the electrostatic powder is made into a negative electrode. The plugged line is negatively pressed. That creates a piezoelectric field in two ways. Because the arc is caused at the negative pole. The sprayed coating particulate medium can be charged and further atomized. According to the same sex, the basic principle of homosexual repelling. Granular architectural coating materials that have been induced to electrify are affected by electric field forces. Directly flow along the power line into the surface layer of the positively coated object, and deposit a layered film with a well-balanced and firmly adhered film.

When the air is compressed as a carrier gas, the electrostatic powder is sent from the powder supply barrel through the powder tube to the water-blocking rod of the spray gun, because the water-blocking rod is connected to the corona discharge caused by the negative pressure, causing The concentrated negative electricity causes the powder to carry negative electricity with it, and enters the electric field with high electric field strength. Under the two-way effect of electrostatic force and transporting vapor, the powder shapely flies to the surface layer of the workpiece of the grounding device to produce a thin and well-balanced powder layer. It is then heated and dried to convert to a durable polyurethane coating. Painting construction process Pre-treatment, drying, removal of water, spraying, inspection, baking, inspection, and inspection of a finished product.

Using the basic principle of electrostatic induction sucking, a layer of electrostatic powder is sprayed evenly on the surface of the steel; the powder that has fallen is acquired according to the acquisition system software and can be reused after sieving.

Therefore, powder electrostatic spraying technology can be widely used in surface protection and decorative spraying of metal parts such as instrumentation, household appliances, electromechanical equipment, automobile ships, light industrial equipment, furniture machinery and building materials. From the technical point of view of spray paint used at this stage, powdered electrostatic spray has its unique advantages in industrial production spray.