product introduction

With the rapid development of the electronics manufacturing industry, the demand for intelligent and automated material management is growing. The intelligent SMT tray and silo system launched by FISMASH is an efficient material storage and management solution for modern SMT production lines. It has multiple advantages such as high intelligence, space saving, and fast access, and is widely used in EMS, OEM/ODM, semiconductors and other fields.

Product Overview

Intelligent Electronic Tray Silo is mainly used to store 7-inch and 13-inch trays and pallet materials commonly used in SMT patch production. It has many intelligent functions such as automatic material loading and unloading, barcode recognition, MES/ERP system docking, etc. The equipment is divided into two structures: single module (P/S series) and double module (DU series) to meet the needs of different production lines.

Core Advantages

🔹High-capacity storage

- C-2000 Series: can hold 2000 trays

- C-3000 series: can accommodate 3000 trays

- C-4000 series: can accommodate 4000 trays

- Supports trays of different specifications such as 7″/8mm and 7″/12mm

🔹 Efficient feeding and discharging

- The average tray retrieval time is only 8~10 seconds/tray

- Supports automatic batch loading of more than 8,000 trays per day

🔹 Intelligent recognition system

- Equipped with 1D/2D barcode automatic recognition device

- Scanning range up to 300mm×400mm

- Can realize unmanned batch scanning and warehousing operations

🔹 System connection and scalability

- Open standard interface, supports MES/ERP system docking

- Optional AGV docking, robotic arm, visual recognition, labeling machine and other equipment to build an intelligent logistics system

🔹Stable environmental control

- Temperature range: 10°C~35°C

- Humidity range: 25%RH~75%RH

- Temperature and humidity monitoring module can be integrated

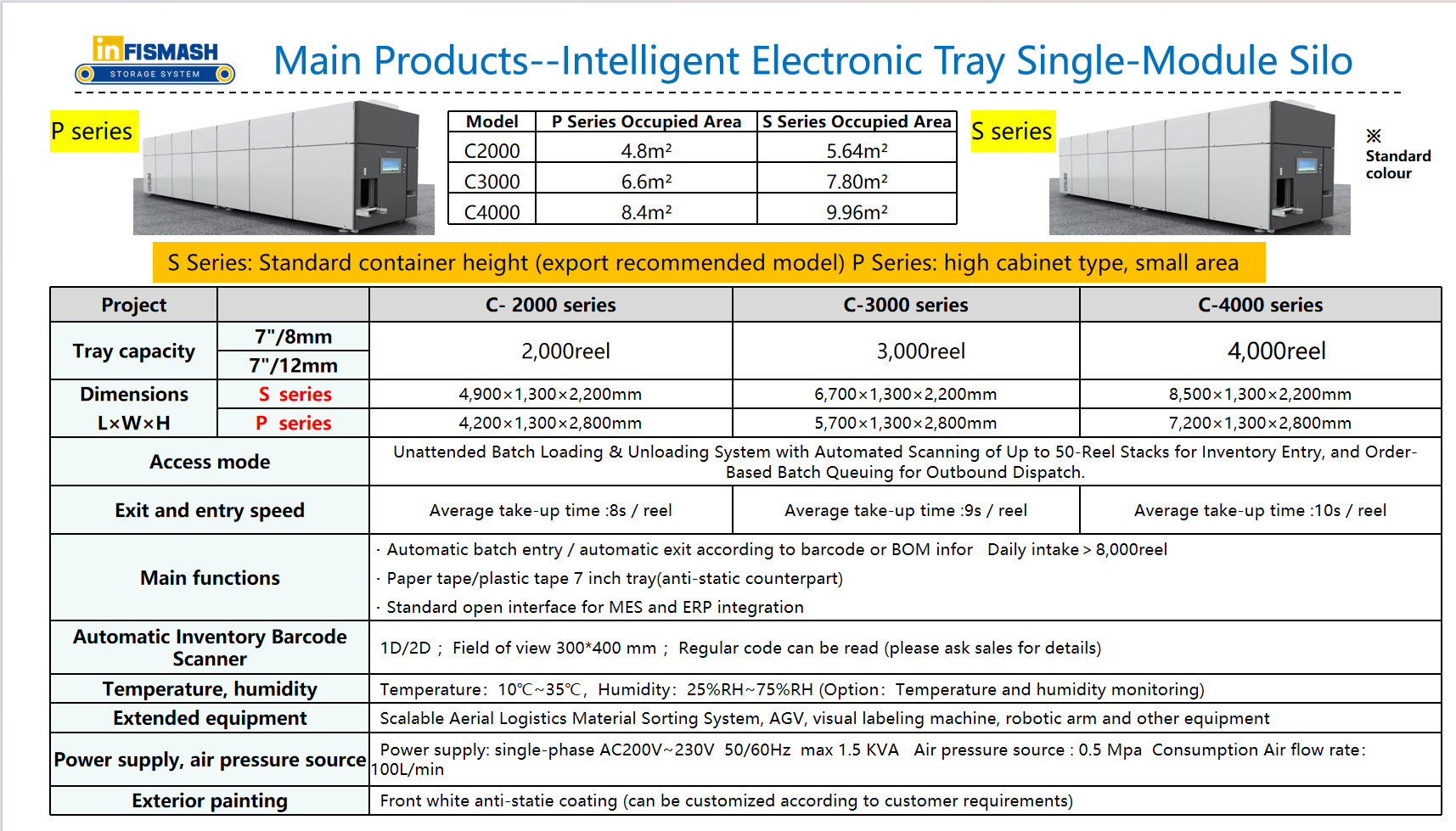

| Model | P Series Occupied Area | S Series Occupied Area |

| C2000 | 4.8m² | 5.64m² |

| C3000 | 6.6m² | 7.80m² |

| C4000 | 8.4m² | 9.96m² |

| Project | C- 2000 series | C-3000 series | C-4000 series | |

| Tray capacity | 7″/8mm | 2,000reel | 3,000reel | 4,000reel |

| 7″/12mm | ||||

| Dimensions | S series | 4,900×1,300×2,200mm | 6,700×1,300×2,200mm | 8,500×1,300×2,200mm |

| L×W×H | P series | 4,200×1,300×2,800mm | 5,700×1,300×2,800mm | 7,200×1,300×2,800mm |

| Access mode | Unattended Batch Loading & Unloading System with Automated Scanning of Up to 50-Reel Stacks for Inventory Entry, and Order-Based Batch Queuing for Outbound Dispatch. | |||

| Exit and entry speed | Average take-up time :8s / reel | Average take-up time :9s / reel | Average take-up time :10s / reel | |

| Main functions | ・Automatic batch entry / automatic exit according to barcode or BOM infor Daily intake>8,000reel | |||

| ・Paper tape/plastic tape 7 inch tray(anti-static counterpart) | ||||

| ・Standard open interface for MES and ERP integration | ||||

| Automatic Inventory Barcode Scanner | 1D/2D ;Field of view 300*400 mm ;Regular code can be read (please ask sales for details) | |||

| Temperature, humidity | Temperature:10℃~35℃,Humidity:25%RH~75%RH (Option:Temperature and humidity monitoring) | |||

| Extended equipment | Scalable Aerial Logistics Material Sorting System, AGV, visual labeling machine, robotic arm and other equipment | |||

| Power supply, air pressure source | Power supply: single-phase AC200V~230V 50/60Hz max 1.5 KVA Air pressure source : 0.5 Mpa Consumption Air flow rate:100L/min | |||

| Exterior painting | Front white anti-statie coating (can be customized according to customer requirements) | |||

🌟2023 Customer Case Showcase

In 2023, FISMASH intelligent SMT tray and silo system will be widely implemented across the country, helping many electronic manufacturing companies to achieve intelligent upgrades in production sites. Our products have been highly recognized by customers for their high capacity, fast response, and friendly system integration. The following are some of the key cooperative customers:

🔹Foxconn China

Deployed several dual-module intelligent silos (DU-SILO), deeply integrated with Foxconn’s MES system. Enabled intelligent scheduling and handling of high-frequency inbound/outbound materials.

🔹 Damaoruike

Provided the C-3000 intelligent silo to multiple SMT lines, realizing unmanned line-side warehousing and significantly improving material turnover efficiency.

🔹 Epson Precision Electronics

Adopted the C-4000 P-series silo to centralize storage and distribution of large batches of reels, effectively reducing manual handling errors.

🔹 Panasonic Industrial Devices SUNX

Provided a highly customized integration plan to meet their stringent standards for stability and traceability in manufacturing workflows.

For more project details or to schedule an on-site demonstration, please contact our sales and technical teams. We are committed to delivering tailor-made solutions to help you build the next generation of smart manufacturing!