Sheet Metal Storage System VLS

1. Overview And Features

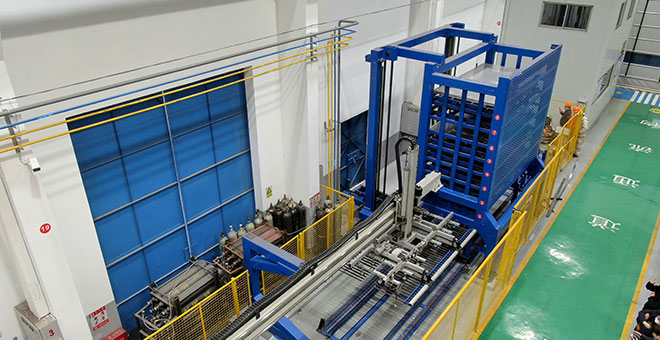

Infismash 6020-5T or 4020-3T consists of material tower, hoist, pallet, loading and unloading system, and material storage management system.

Material storage system

Assembling with a rectangular tube, and the lifting column is processed by the gantry milling machine to ensure the running precision and stability. The double column lifting mechanism is adopted, and the well-branded motor is used to drive the pallet plate lifting through the double-row chain drive, the tractor on the hoist pulls the hook on one side of the tray to access the storage. The overall structure is simple and generous, and the equipment is easy to disassemble and carry. With precise positioning, stable operation, fast and flexible functions.

Hoist

The double-column lifting mechanism is adopted to realize the lifting and lowering of the plates on the tray by the double-row chain driving, and the tractor on the lifting machine pulls the hooks on the side of the tray to realize the ingress and egress. It is accurate in positioning, stable in operation, fast and flexible.

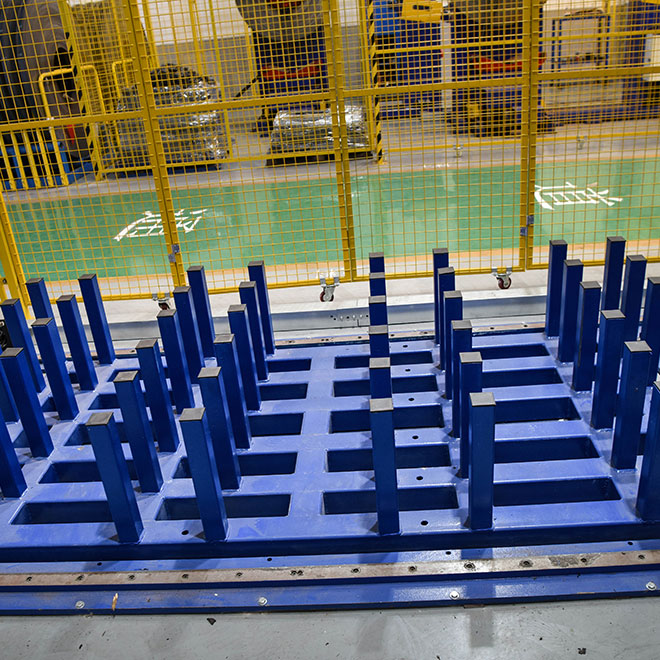

Tray

It is welded by rectangular tube, and four hooks are welded on both sides of the tray. The guide post on the tray can realize the initial positioning of the sheet.

Loading rack

It is welded by round bar and can support and position of the whole plate.

Material storage management system

It adopts Siemens touch screen industrial computer control, including “plate input, plate output, plate loading, plate unloading, plate input and output record statistics, inventory statistics, inventory warning, fault warning prompts and other interfaces. English interface operation is simple and convenient. It is easy for the operator to learn immediately.

Features

- Using a three-dimensional material warehouse to store plates, saving factory space.

- Adopt intelligent management system to quickly grasp the inventory of plates in real time.

- One-button start, automatic operation.

- Large-capacity storage positions, safe and fast operation.

- The professional team is designed to work in the workshops of most factories.

- Improve work efficiency, reduce the risk of injury, and reduce the labor intensity of staff.

- Customer satisfaction with automated production site.

- On-site 5S management is neat and orderly, and the overall site is convenient for customers to visit.

2. Description of the sheet metal storage system

Adopt advanced design concept and standard modular design. The shape is beautiful and the atmosphere is easy to install and debug on site. It consists of material library, an automatic loading and unloading system, and an electrical control system. Automated production of laser processing.

Material tower

After processing by rectangular tube gantry milling machine, it is assembled by two main side plates, and the whole machine is assembled by bolts. The number of layers is 15 layers, each layer has a height of 400mm and the load is 5T. The lower part of the plate is not equipped with wooden pallets to enhance the storage space of the plates and facilitate the positioning of the plates. When the material is replenished, the forklift or the vehicle is used with the loading positioning table to place the plate at the origin of the pallet. At the same time, the material management system automatically records the material specification, material number, quantity and other information, which is the basis for automatically picking up the plate. The sheet tray is stored by the hoist to the vacant position of the tower. When a certain size of sheet is required, the hoist automatically picks up the material from the corresponding location and exits the warehouse.

Hoist

The lifting device adopts double column design, lifting speed: 0-15 m/min; translation speed: 0-10 m/min; It consists of the motor and reducer on the top of the hoist, the bearing and the chain on the side of the column. Lift the material tray up and stop at any of the cargo racks in the tower and ensure that the pallet rails are docked between the two. The system accurately identifies the height position of each layer by means of a laser scanner. The translational conveying device completes the feeding and discharging by the driving mechanism installed on the hoisting machine, and drags the tray in the material tower into or out.

Roller tray

The roller tray is formed by pipe welding, which can load 3T, finite element analysis of the pallet, and the positioning pin is mounted on the pallet for positioning of the material; the two sides of the tray have two U-shaped notches, and when the translation device moves, the profile pulls The block will hook the U-shaped notch on the tray to realize the tray access to the library.

Loading positioning table

The loading positioning table is welded by square tube and round bar to realize the support and positioning of the whole plate.

Work Process

- 1. When the material is fed, the forklift or the vehicle is used with the loading positioning table to place the plate at the origin position of the tray.

- 2. The hoist automatically sends the plates to the empty position of the tower, and the system automatically records the plate information.

- 3. When a plate of a certain specification is required for production, the hoist automatically takes the material out of the corresponding location

Electrical control system

The control system is reasonable in design, simple in operation, beautiful in appearance, advanced in intelligent storage management and automatic loading and unloading. With the most advanced and mature control systems and technologies, it has high precision, high reliability and high response speed. The lifting mechanism and the translation mechanism softly stop, ensuring control accuracy while reducing noise and inertia. Long-term operation is stable and reliable, with low noise and long life. The components adopt the first-line brand: PLC adopts Siemens with communication function, the inverter adopts Yaskawa, and the PLC software has safety protection and fault alarm reminding function. The program must provide a complete motor protection circuit: in the event of a motor overload, the motor protection circuit will cut off the power supply to the drive and the device will stop. After the fault has been eliminated, the motor can be switched back on by using the motor protection circuit again. Emergency stop device: In an emergency, the device can be stopped immediately by means of an emergency stop switch. The device must not be restarted until the device failure has not been completely eliminated. The man-machine interface has an automatic and manual operation interface, and each interface has an operating state and a fault status indicator to monitor the running status of the device in real time. It is equipped with numeric keys, function keys, running instructions, operation prompts, automatic fault display and other convenient operations.

Conditions of Use

- The equipment control uses many electronic products, and the temperature requirement for the environment is 0 °C-55 °C;

- The electrical control of the equipment is highly precise, and the humidity to the environment is 15 to 90% RH (no condensation);

- The equipment uses three-phase five-wire power input. The power supply requirements are phase voltage 380V, voltage fluctuation ±10%;

- The frequency requirement of the power supply to the power grid is 50HZ required by the normal power grid, and the frequency fluctuation is ±5%;

- The installation of the three-dimensional material library needs to be the foundation. Please wait for the contract to see the foundation map of our company.

Communication online

When the bus communicates with the laser machine, the laser machine needs to open the communication signal and send the work instruction. The equipment manufacturer needs to arrange the electric factory division to debug together free of charge. Communication can also be detected by adding sensors.

Equipment color

The color of our equipment is generally blue and white, and can also be customized according to customer needs. The color code number of the equipment provided by the customer within one week after signing the contract.

3. Equipment specifications

| Srl. No. | Item | Specification |

|---|---|---|

| 1 | Plate size | 6000*2000MM |

| 2 | Plate thickness | 1-20MM |

| 3 | Layer height | 400MM |

| 4 | Storage plate net height | 250MM/layer |

| 5 | Storage layers | 15th layers |

| 6 | Rated load | 5T/layer |

| 7 | Vertical lifting speed | 15M/min |

| 8 | Horizontally moving speed | 10M/min |

| 9 | Repeat positioning accuracy | 1MM |

| 10 | Control system of material library | Independent research and development |

| 11 | Operation method | automatic / manual |

| 12 | Total load of material library | 75T |

| 13 | Vertically lifting motor power | 18.5KW |

| 14 | Horizontally moving motor power | 0.75KW |

4. Equipment parts brand list

| Srl. No. | Item | Brand | Quantity |

|---|---|---|---|

| 1 | PLC | Siemens, Germany | 1 |

| 2 | Frequency converter | Yaskawa, Japan | 2 |

| 3 | Touch screen | Weilun,China | 1 |

| 4 | Main electrical components | Schneider,France | Several |

| 5 | Coupling | Chinese famous brand | Several |

| 6 | Bearing with seat | Chinese famous brand | Several |

| 7 | Double row chain | Chinese famous brand | Several |

| 8 | Reducer | Chinese famous brand | Several |

| 9 | Linear Guide | HIWIN, Taiwan | Several |

| 10 | Laser scanner | Leuze, Germany | 1 |

5. Transportation, installation, commissioning and acceptance training

Our company’s equipment will send to the customer’s designated site by sea. It is fully dispatched by our company before arriving at the customer site. Upon arrival at the customer’s site, the customer will assist our company’s engineers to unload and hoist the equipment free of charge. The supplied accessories arrive at the site with the equipment.

All equipment provided in the sales contract is installed and commissioned by our company. The company’s installation and commissioning personnel arrive at the site with the equipment. The installation and commissioning of the equipment are carried out by our engineers. The installation and commissioning time of the equipment is 20 working days. After the commissioning is completed, the equipment trial will be carried out for three days. After the trial is completed, the acceptance is based on the technical parameters mentioned in the contract and technical agreement.

After the equipment has been checked and accepted. Our engineers will train the trainees of the customer company how to use the machine until the trainees fully learn. The main training items are as follows:

- 1.The structure of the equipment and the operation process of the equipment.

- 2.Operation of the equipment.

- 3.Equipment maintenance and troubleshooting.

- 4.Safe operating practices for equipment.

6. Quality assurance and after-sales service

The warranty period of the equipment is 1 year, counting from the acceptance of the inspection. In the event of a non-human failure within the warranty period, the equipment will be repaired free of charge for the customer.

After the equipment has passed the warranty period, our company will send engineers to repair, and only charge the cost.

After receiving the customer’s problem feedback, our company engineers will immediately guide the troubleshooting point. When the customer is unable to process, our company engineers will arrive at the customer’s site within 24 hours for fault repair.

Our company provides remote technical support for customers 24 hours a day.

Regarding equipment spare parts, our company has stocks, which can be provided at any time to ensure the normal operation of the equipment.