Vertical Lift Module (VLM) Automated Storage Systems

Intelligent, High-Density VLM Storage Solutions

KenWei designs and manufactures advanced Vertical Lift Modules (VLMs) to revolutionize your storage and retrieval operations. Ideal for manufacturing, distribution, and warehouse environments, our innovative VLM towers are engineered to **maximize your vertical space**, dramatically improving storage density for both bulky and heavy items while optimizing your workflow.

What is a Vertical Lift Module?

A Vertical Lift Module (VLM) is an enclosed automated storage and retrieval system (AS/RS) consisting of two columns of trays with an inserter/extractor in the center. At the push of a button or scan of a barcode, the extractor automatically locates and delivers the tray with your stored goods to an ergonomic access opening. Thanks to its **modular design**, a VLM system can be adapted to any ceiling height, ensuring you make the most of your available space.

How Does a VLM System Work?

Our VLM systems operate on the “goods-to-person” principle, bringing items directly to the operator to eliminate wasted time walking and searching. The process is simple:

- The operator selects the required item via the control interface.

- The internal extractor travels vertically to locate the correct tray.

- The tray is retrieved and delivered quickly and quietly to the access bay.

- An integrated LED system can pinpoint the exact item to be picked, ensuring accuracy.

This automated process can **reduce employee work time by over 45%** and is far more efficient than traditional shelving.

Key Benefits of VLM Implementation

By integrating a KenWei VLM system, you can master your intralogistics challenges, from managing a greater variety of items to offering 24-hour service. Here are the main advantages:

- Maximize Storage Space: Dramatically increase storage capacity on a minimal footprint.

- Boost Productivity: Speed up picking times and increase your operational throughput.

- Improve Accuracy: Reduce picking errors with software-guided processes.

- Enhance Security: Enclosed storage protects valuable inventory from dust, damage, and unauthorized access.

- Improve Ergonomics: Items are delivered at an optimal height, reducing bending, reaching, and lifting for operators.

- Flexible & Scalable: Modular design allows for easy adaptation to your changing business needs.

Our Vertical Lift Module Options

The KenWei team has extensive experience designing and integrating VLM systems for a wide range of products. We’ll work with you to develop the perfect solution for your specific needs, including Shelf Carousels and Pallet Lift Modules.

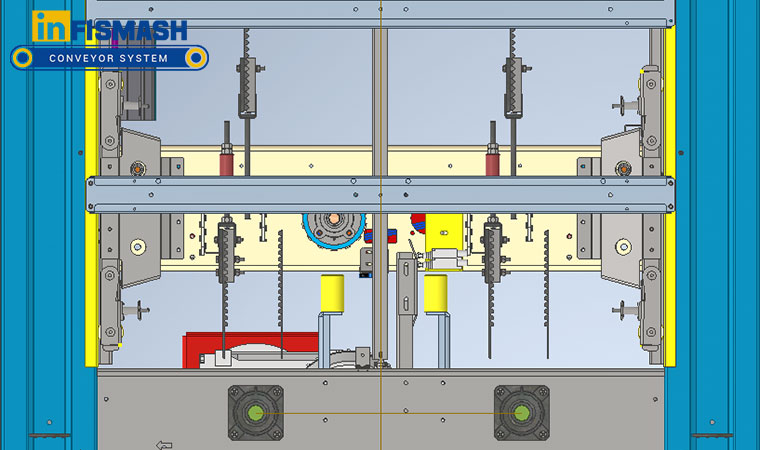

Selective VLM (Shelf Carousel)

Also known as a Shelf Carousel, this intelligent VLM uses bins as the storage unit, making it perfect for the dense storage of small parts, electronic components, or files. It can be integrated with conveyor lines and AGVs to create a fully unmanned, automated logistics workflow, significantly improving efficiency and reducing operational costs.

Pallet Lift Modules (Pan Carousels)

Designed for heavier and bulkier items, the Pallet Lift Module (or Pan Carousel) uses pallets as the storage unit. An automatic height detection system ensures safe and efficient storage of goods. This system is ideal for storing tools, machine parts, or special-shaped materials securely and reliably, while maintaining an accurate, real-time inventory.

Infismash Shuttle Models & Technical Data

Every Infismash Shuttle is configured to meet your specific needs. Explore our standard models below.

Infismash Shuttle 250

Flexible solution for small parts and lightweight inventory.

The Shuttle 250 is our premier solution for storing and retrieving small-sized inventory. With a maximum tray load of 250 kg, its compact layout is adaptable to various space requirements, offering maximum storage potential on a minimal footprint. It is also suitable for specialized environments, such as temperature-controlled or clean room conditions.

Infismash Shuttle 500

Highly compact storage for medium loads.

The Shuttle 500 handles loads up to 500 kg per tray. It is ideal for efficiently storing and retrieving heavy tools, components, or spare parts. Its highly flexible design allows for a wide variety of options that can be integrated before or after installation to cater to your changing business needs.

Infismash Shuttle 1000

Manages heavy-duty loads up to 1,000 kg.

Achieving new standards in load-carrying capacity, the Shuttle 1000 is perfect for storing medium-heavy to heavy parts. You can even use a forklift to stack and store Euro pallets directly in specifically designed trays, saving space and making it faster to locate items, thereby reducing costs and increasing productivity.

Standard Technical Data

| Shuttle 250 | Shuttle 500 | Shuttle 1000 | |

|---|---|---|---|

| Width | 1,706 to 4,000mm | 1,706 to 4,000mm | 1,706 to 4,000mm |

| Depth | 2,341 and 3,100mm | 2,341 and 3,100mm | 2,341 and 3,100mm |

| Height | 2,550 to 12,000 mm | 2,550 to 12,000 mm | 2,550 to 12,000 mm |

| Load per Tray | Up to 250 kg | Up to 500 kg | Up to 1,000 kg |

Available Options & Add-ons

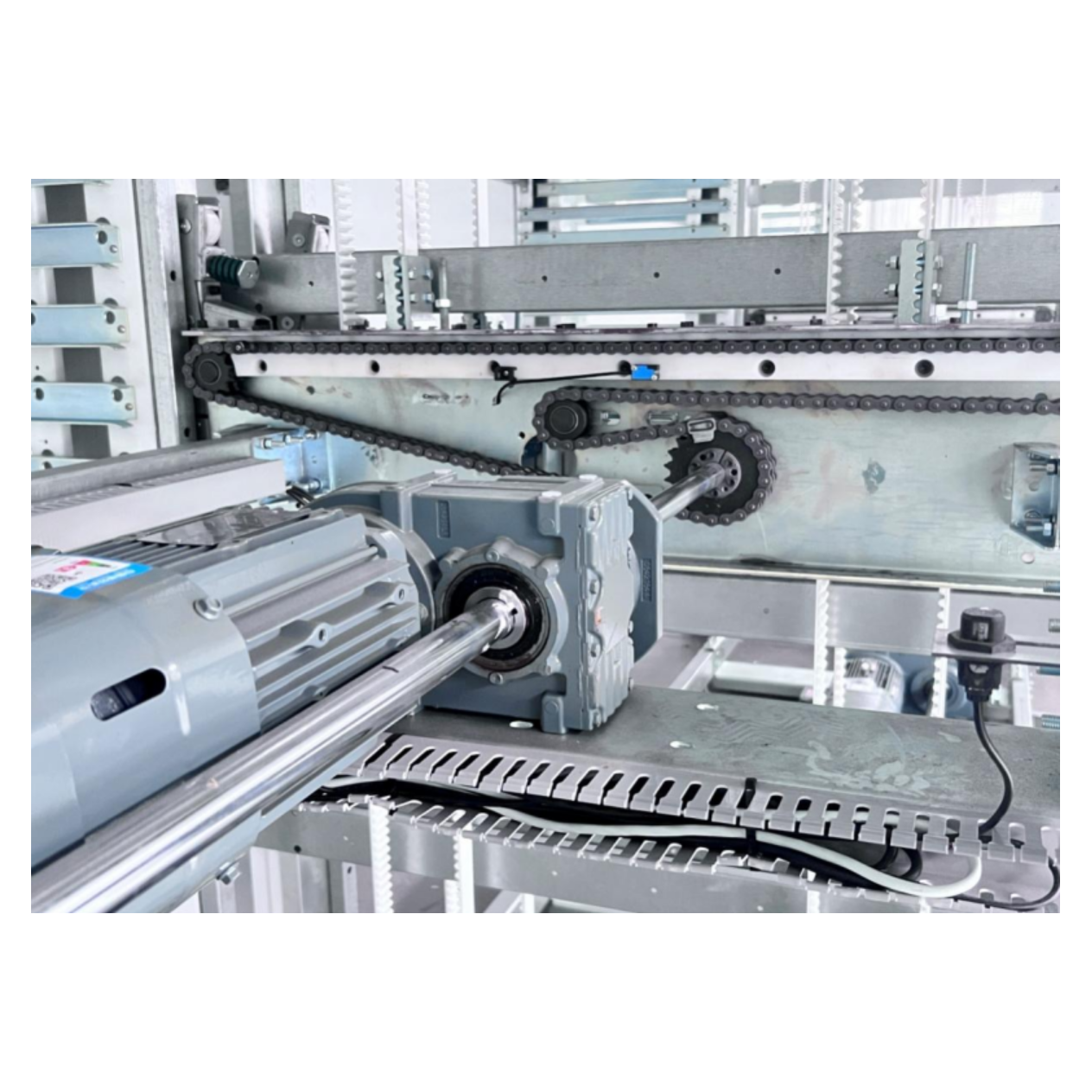

High-Speed Lifting Drives

Multifunction Trays

Ergonomic Access Point

Ready to Transform Your Storage?

Our team provides custom-made solutions precisely for your individual storage requirements. Let us help you design the perfect VLM system.